top of page

Machinery Showcase

J-Box Bleaching:

This J-Box Bleaching Plant is designed for the continuous bleaching of grey fabric into pure white, preparing it for dyeing or printing. The fabric passes through a controlled chemical treatment using sulphuric-based solutions, held under heat and pressure for maximum whitening effect. With an output capacity of 2 tons/day, this fully automatic plant ensures uniform whiteness, softness, and strength in the processed fabric—ideal for textile industries requiring consistent pre-treatment results.

Rotary Screen Printing

High-performance 12-color Rotary Screen Printing Machine designed for precision textile printing on continuous fabric rolls. Ideal for bulk production, it uses rotating screens to apply up to 12 colors simultaneously with sharp detailing and vibrant results. Engineered for high-speed operation, consistent registration, and seamless fabric handling, this automatic machine is a top choice for large-scale textile manufacturers. Suitable for cotton, polyester, viscose, and blended fabrics.

Maxi Close Type Jumbo Jigger Machine

Efficient and fully enclosed jigger dyeing machine designed for high-volume dyeing, bleaching, and washing of woven fabrics. Ideal for maxi dress materials and wide width textiles, it ensures uniform color penetration with low liquor ratio and automated process control. Perfect for precision textile processing with minimal fabric tension

Soft Flow Fabric Dyeing Machine

Advanced soft flow dyeing machine specially designed for delicate fabrics like cotton, rayon, viscose, and synthetics. It uses gentle fabric circulation with low liquor ratio for uniform dyeing, reduced creasing, and energy-efficient operation. Ideal for processing lightweight garments and knitted fabrics with soft handling and vibrant results.

Stenter Machine

This high-performance Stenter Machine is designed for heat setting, drying, and finishing of fabric. Engineered for precision and energy efficiency, it ensures uniform width control, wrinkle-free output, and high-quality finishing — ideal for textile processing units seeking consistent and superior results.

Loop Ager / Steamer (PLC Based – Moist & Super Heated Steaming)

The Loop Ager is a precision-engineered machine designed for controlled steaming of printed and dyed fabrics. Equipped with a PLC-based system, it ensures accurate temperature, humidity, and timing control. Ideal for fixation of reactive, disperse, and vat dyes, it offers both moist and super-heated steaming options. Its continuous loop design allows smooth fabric flow with minimal tension, ensuring excellent color development, penetration, and fastness. Suitable for woven and knitted fabrics, it’s an essential unit in high-quality textile finishing.

U-Tube Fabric Dyeing Machine (Rapid Jet Dyeing – PLC Based)

A high-efficiency, PLC-controlled U-Tube fabric dyeing machine designed for low liquor ratio operations. Ideal for rapid dyeing of delicate to heavy fabrics, this machine offers superior fabric circulation, minimal tension, and optimized dye penetration. Its energy-efficient design ensures consistent dyeing results with minimal water and chemical usage, making it perfect for modern textile processing units.

flat belt printing machine

High-resolution flatbed textile screen printing machine designed for precise and multicolor printing on African printed fabrics, featuring multiple print stations with automatic fabric feed and alignment system.

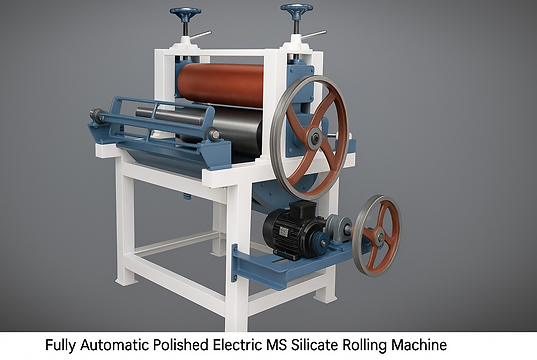

Fully Automatic Polished Electric MS Silicate Rolling Machine

This high-performance rolling machine is engineered for precision in silicate application across textile fabrics. Constructed with mild steel (MS) for durability, it features a polished finish for enhanced longevity and appearance. The machine operates on an electric motor for smooth, automatic rolling, ensuring consistent coating or pressing. Its robust frame, adjustable rollers, and manual control wheels provide flexibility in operation, making it ideal for textile manufacturing units aiming for efficiency and quality in their silicate processing.

Automatic Round Textile Jigger Roll Machine

An advanced, fully automatic jigger dyeing system designed for continuous fabric processing with uniform dye penetration. Engineered with high-grade stainless steel rollers and precision control systems, this machine ensures smooth fabric movement, efficient dye utilization, and minimal tension throughout the cycle. The robust structure and PLC automation offer excellent repeatability, energy efficiency, and operator safety. Ideal for dyeing woven fabrics in open width, this jigger machine supports a wide range of fabric types and dyeing applications in modern textile manufacturing environments.

Industrial Biomass Boiler System for Steam & Heat Generation

This is a high-resolution image of an industrial biomass boiler system. It features two large stainless steel boilers connected by a horizontal duct, with a pile of cylindrical biomass briquettes in front. The setup is housed in a metal-structured warehouse and is used for steam or heat generation in industrial processes.

bottom of page